HOMAG edge banding units are the result of more than 2000 processing centers for edge banding and are a complete family of edge banding units for a wide range of applications.

The Homag BAK is a contour edgebanding and edgefmishing center with CNC control, for the production of batch sizes according to specific customer and production requirements.

Robust and variable The torsionally rigid dual frame construction of the machine stand forms the foundation for the extreme processing precision of all units. The variable stand design permits the …

Thanks to training sessions tailored to meet your individual needs, your machine operators will be able to optimally operate and maintain HOMAG machines · In conjunction with this, you will receive …

Safe hot-melt glue application rent factors. On HOMAG machines, the workpiece preheating, application unit, heated gluing roller, system, melting unit, magazine and pressure zone are perfect-ly aligned.

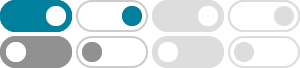

Series EDGETEQ S-356 – the highly flexible all-rounder. HOMAG gluing system high quality gluing from top to down, fresh glue and accurate gluing temperature. Snipping unit more stable and strong …

New applications for operating and controlling machines and systems (e.g. NCCenter in the PC87 control system on CNC machines or woodCommander 4 on throughfeed machines) · Fresh, …

woodWOP – the CNC programming system from HOMAG mming system from HOMAG. The centerpiece of the innovative user interface is the large graphic area in which the workpiece is displ …

- [PDF]

HOMAG CUBE

The HOMAG CUBE is a mini-computer that is used for assistance systems, e.g. to control LED strips for an edgeband shelf, or to identify material for a label printer.

For customers with very demanding automation requirements, HOMAG ofers tailored horizontal storage systems — ranging from small systems for woodworking shops to large industrial solutions.